Technologies of ELT Sensor

Quality Technology, knowhow and Customer support

- 1. How does a non-dispersive infrared (NDIR) gas sensor work?

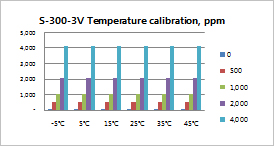

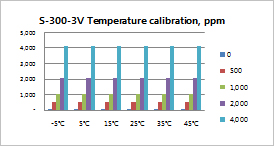

- The world best temperature change compensation throughout the whole operating Temperature range, let alone persistent statility and uncompatible accuracy even for small sensor.

- 2. High Stability and Reliability

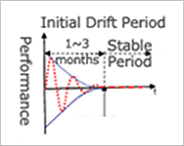

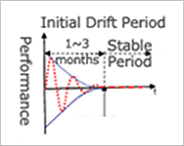

- The product ensures a long time stability and high reliability.

Minimum drift against time: ELT SENSOR��s own technology in drift changes

- 3. There are few deviations between sensors and quality is uniform across products.

- 4. We provide a wide range of products.

- Our customers can select products that fit their applications; such as general ventilation, agriculture, ultra mini size, low power consumption, multiple input power (3V, 5V, 12V, and 24V), high stability, single beam or double beam

- 5. Consultation with customers for the development of new products

- We design, develop and produce our products in our own facility.Therefore we develop and supply the customized products to meet the demand from world leading Customers.

Retained technologies: Optical cavity technology, temperature calibration technology, hardware design technology, Firmware design technology, size minimization technology, multi sensor co-design technology, etc.

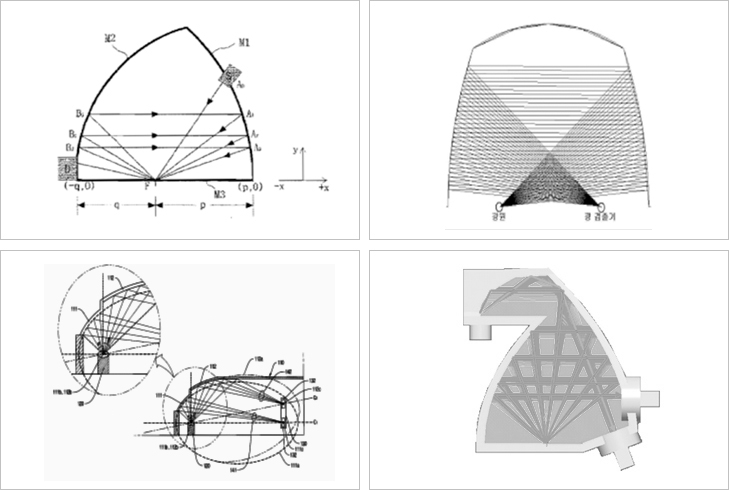

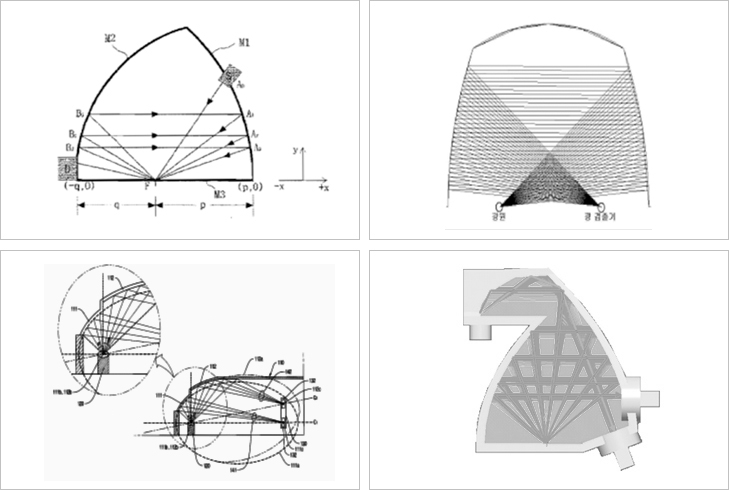

- 1. Optical Path Design Technology

- The core technology is to fabricate best performance with longer optical path even with small cavity sensor.

- The ELT Sensor has the biggest number of optical cavities for CO2 sensor.

- Characteristics: small size but long optical path for high performance, single and dual optical path, etc.

- Measurement Gas: CO2, CO, HC (CH4, C2H4, C3H8, C4H10), NH4, etc.

- Gas Concentration: All ppm range of CO2, LEL % range of CH4/C3H8/C4H10.

- Long and efficient path length

- Multi optical path theory

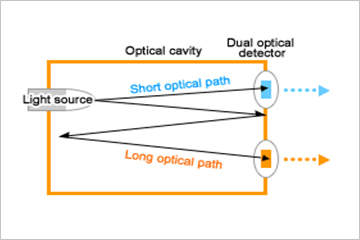

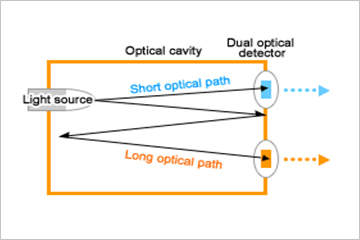

- Optical cavity, where 2 kinds of gases are detected simultaneously with 2 optical paths

- Optical paths are composed of a long optical path and short optical path.

- The Short optical path detects CO2 and the long optical path detects the gas such as CO or NH3 with high optical absorption rate.

- 2. NDIR Correction Technology

- It is possible to re-correct very simply and in a very short amount of time by applying automatic correction or 1-point manual correction method with the ELT SENSOR product.

1) Automatic correction (ACDL: Automatic Calibration of Dimming Light Sources)

- Applied model: whole models

- Correction Period: every 7days, or 30days in each models

- Tolerance of data after re-correction: lower than 1%

- Correction method (process): correction by S/W or H/W signal

- Correction Point: 0 ppm or 400 ppm (CO2) correction, 0 ppm correction (CO, CH4, C3H8, C4H10 etc.)

The ELT SENSOR��s function approaches to the correction of 99% of factory calibration status

by the 1-point ACDL or MCDL