- Technology

- Technology of ELT SENSOR Notice: Undefined offset: 3 in /ii_eltsensor1/www/html/_skin/layout/inc_navigation_middle.php on line 88

Technology of ELT SENSOR

-

-

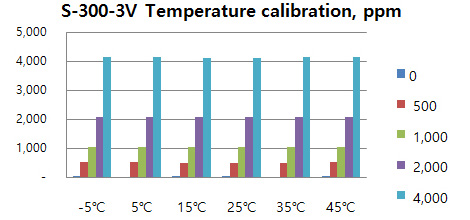

- 01Temperature Effect Compensation and Correction Technology

- With the world best temperature effect compensation and correction technology, ELT’s gas sensors have incomparable high accuracy and consistent stability even for small sensors.

-

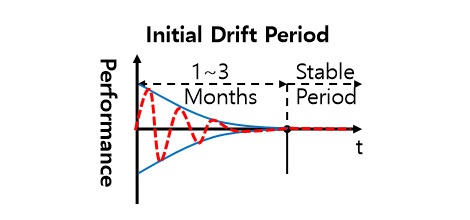

- 02High Stability and Reliability

- Our gas sensors ensures a long-term stability and high reliability with our own technology which can make drift minimize against time.

-

- 03There are Few Deviations between Sensors and Quality is Uniformly High Across Products.

-

- 04We Provide a Wide Range of Products.

- Our customers can select products that fit their applications such as general gas sensors for ventilation, robust gas sensors resistant to 99% humidity for agricultural use, small sensors for little spaces and so on. Also, we have single channel and dual channel sensors which can used for harsh environments such as satellite and some places which needed low- power consumption. To meet customer’s needs, our sensors have some options which can make sensors communicate with other products by various kinds of output such as UART, I2C, Analog, PWM and RS485-Modbus besides 4 kinds of input power (3V, 5V, 12V, 24V).

-

- 05Consultation with Customers for the Development of New Products

- We have been developing and supplying customized products to meet the demand from world leading customers as we design, develop and produce our products in our own facility. Retained technologies : Optical cavity technology, temperature calibration technology, hardware design technology, Firmware design technology, size minimization technology, multi sensor co-design technology, etc.

-

-

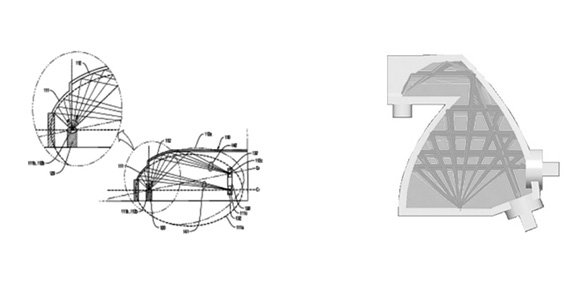

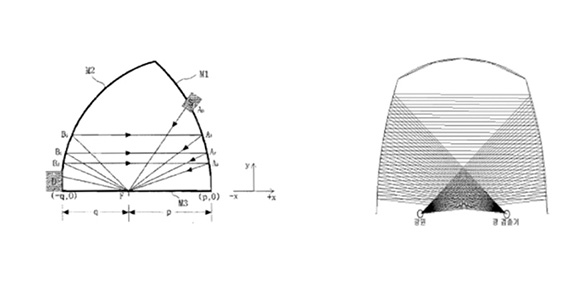

Optical Path Design Technology : The core technology is to fabricate best performance with longer optical path even with small cavity sensor.

- ELT Sensor has the biggest number of optical cavities for CO2 sensor.

- Characteristics : small size but long optical path for high performance, single and dual optical path, etc.

- Measurement Gas : CO2, CO, C-H(CH4, C2H4, C3H8, C4H10), etc.

- Gas Concentration : All ppm range of CO2, LEL % range of CH4/C2H4/C3H8/C4H10.

- Long and efficient path length

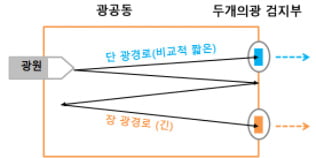

Multi Optical Path Theory

- Optical cavity, where 2 kinds of gases are detected simultaneously with 2 optical paths. (CO2+CO, CO2+CH4 etc.)

- Optical paths are composed of a long optical path and short optical path.

- The Short optical path detects CO2 and the long optical path detects the gas such as CO or NH3 with high optical absorption rate.

NDIR Calibration Technology

It is possible to re-calibrate very simply and in a very short amount of time by applying automatic calibration (ACDL) or 10 minutes manual calibration (10’ MCDL) method with the ELT SENSOR product.

Automatic Calibration (ACDL)

- Applied model : whole models

- Calibration Period : Every 7days, or 30days in each models

- Tolerance of data after re-calibration : Lower than 1%

- Calibration Method (Process) : a) Calibrated by S/W or H/W signal, b) Calibrated with ELT’s own Test Jig board (TRB-100ST, EK-100ST, CMB-10)

- Calibration Point : CO2 sensors : 0 ppm or 400 ppm Calibration

Calibration Point : CO, CH sensors : 0ppm Calibration

ELT SENSOR’s products are all pre-calibrated before shipment.

ELT SENSOR’s products are all pre-calibrated before shipment.